Air Handling Equipment

Air, Liquid Filters and Filtering Systems

Automation Equipment

Brushes, Brooms & Sweepers

Bulk Material Handling

Conveying Equipment

Lifting Products

Mobility Products

Plant and Facility Equipment

Plant and Facility Supplies

Recycling Equipment

Storage Products

Below is useful information about equipment manufactures that specialize in material handling. This is useful information to inform the purchasing agent, design engineer, maintenance supervisor, or property development engineer.

Understanding Material Handling Equipment: Streamlining Efficiency in Operations

Material handling equipment (MHE) plays a vital role in optimizing workflows across industries like manufacturing, warehousing, and logistics. Designed to move, store, control, and protect materials during production, transportation, and distribution, MHE enhances efficiency, reduces manual labor, and improves workplace safety.

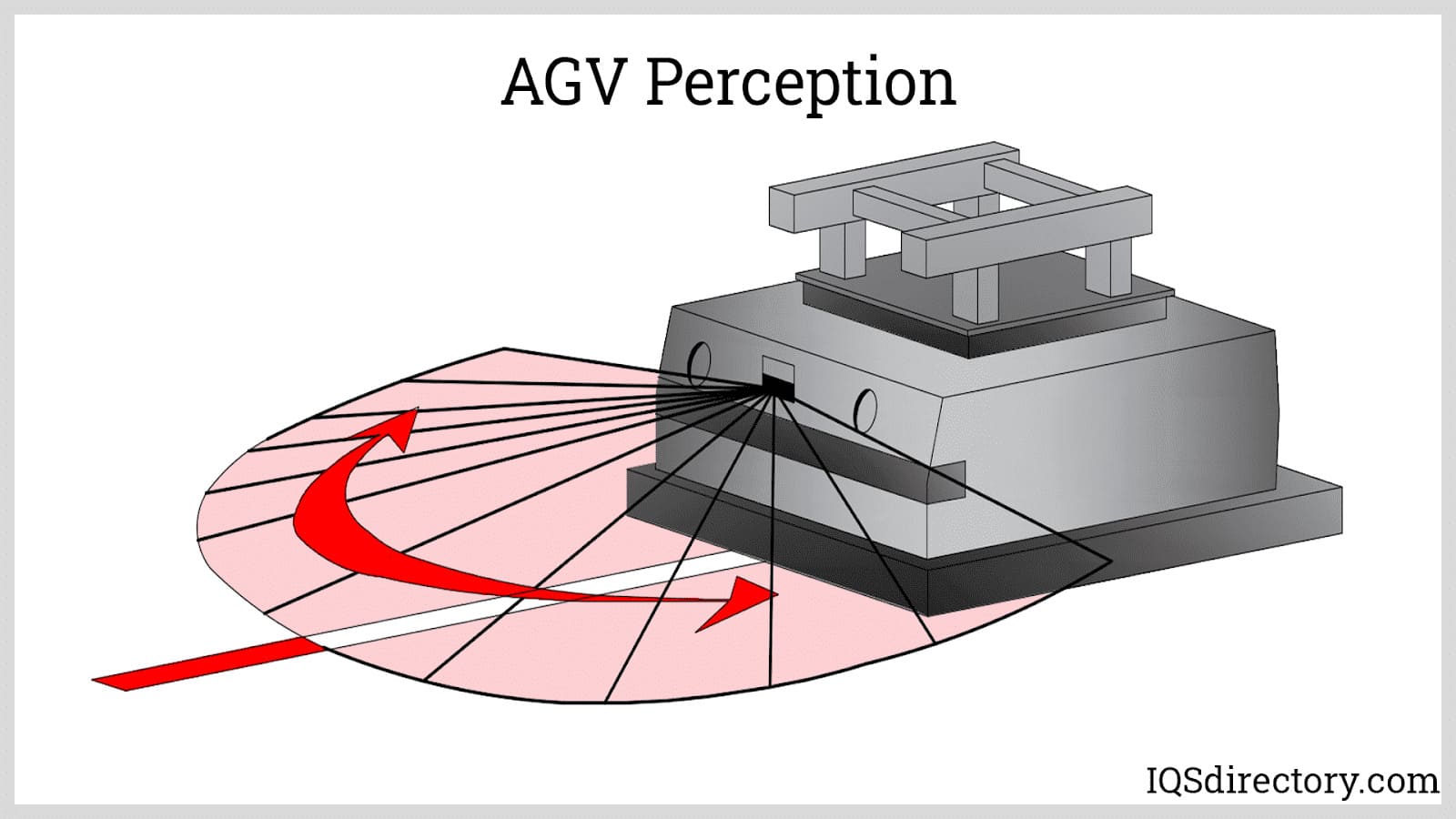

There are several types of material handling equipment, each tailored to specific tasks. Conveyors, such as belt and roller systems, are widely used to transport goods within a facility, ensuring a smooth flow of materials in assembly lines or distribution centers. Forklifts are essential for lifting and moving heavy pallets or bulk items, making them indispensable in warehouses. Cranes and hoists handle oversized loads, often in construction or heavy manufacturing settings, while automated guided vehicles (AGVs) offer a modern solution, using sensors and software to move materials autonomously, reducing human intervention.

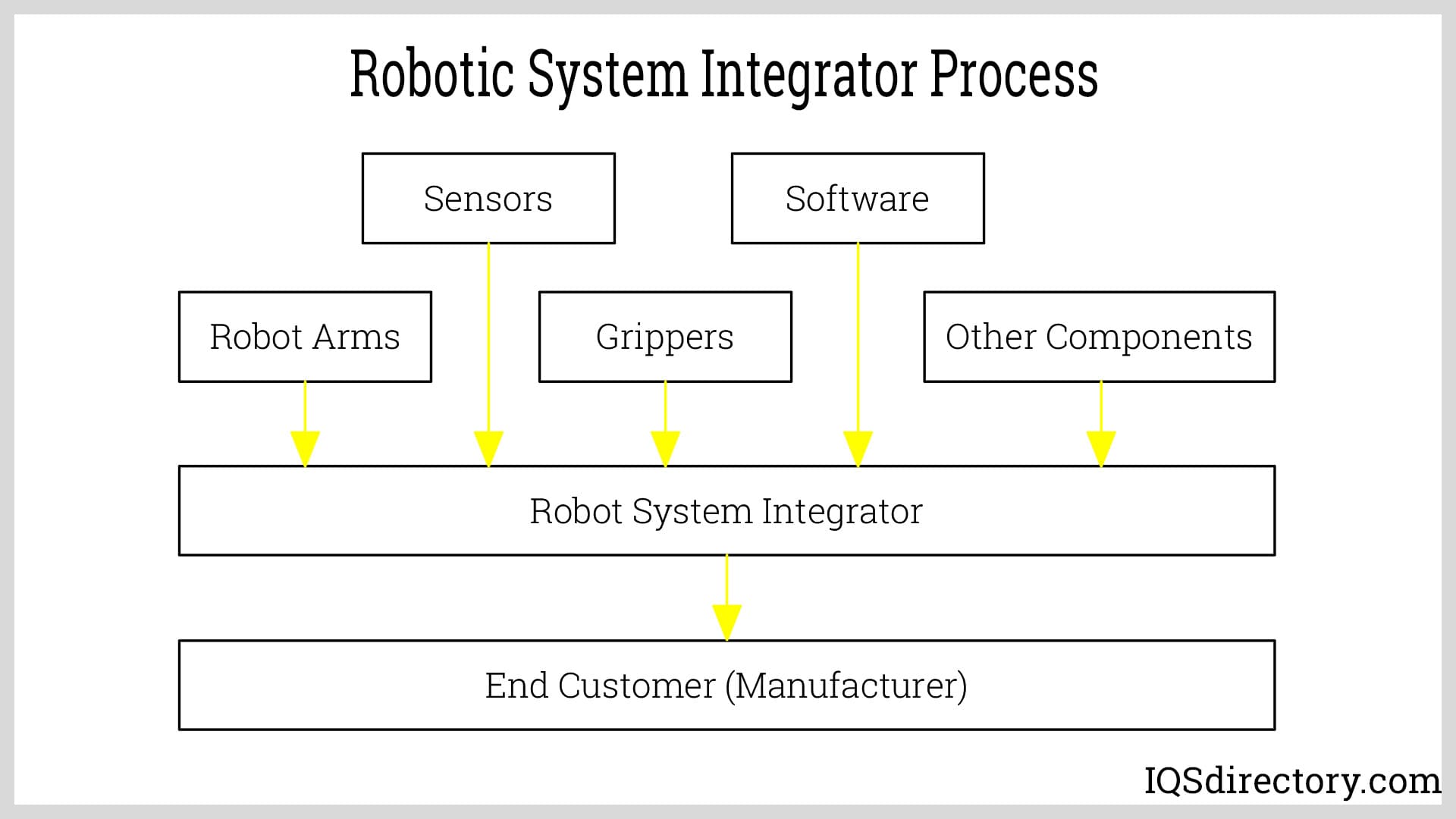

The benefits of MHE extend beyond productivity. By automating repetitive tasks, equipment like pallet trucks and stackers minimizes the risk of workplace injuries caused by manual lifting. Additionally, advanced MHE systems, such as robotic arms and warehouse management software, integrate with IoT technology to provide real-time tracking and data analytics, enabling businesses to optimize inventory management and reduce operational costs.

Investing in the right material handling equipment can significantly impact a company’s bottom line. Selecting equipment that aligns with operational needs—whether it’s a simple hand truck or a fully automated system—ensures smoother processes, safer environments, and higher efficiency. As industries evolve, MHE continues to be a cornerstone of operational success.

Exploring the Types of Material Handling Equipment: Tools for Efficiency and Safety

Material handling equipment (MHE) is essential for moving, storing, and managing materials in industries like manufacturing, warehousing, logistics, and construction. These tools streamline operations, reduce manual labor, and enhance workplace safety. Understanding the different types of material handling equipment can help businesses choose the right solutions for their needs. This article explores the main categories of MHE and their applications.

-

Transport Equipment

Transport equipment is designed to move materials from one location to another within a facility or across sites. Conveyors, such as belt, roller, or chain systems, are ideal for continuous movement of goods in assembly lines or distribution centers, ensuring a steady workflow. Forklifts, powered or manual, are versatile for lifting and transporting heavy pallets, commonly used in warehouses. Automated Guided Vehicles (AGVs) use sensors and software to navigate autonomously, delivering materials without human intervention, which is perfect for large-scale operations like automotive manufacturing.

Read more about Transport Equipment

-

Storage Equipment

Storage equipment maximizes space and organizes materials for easy access. Racks and Shelving, including pallet racks and cantilever racks, store goods vertically, optimizing warehouse space. Stackers are used to stack pallets or crates, ensuring efficient use of vertical storage. Mezzanines create additional floor space in facilities, allowing for more storage without expanding the footprint, often used in retail or e-commerce warehouses.

Read more about Storage Equipment

-

Lifting and Positioning Equipment

This category focuses on lifting and positioning heavy loads with precision. Cranes, such as overhead or gantry cranes, handle large, heavy items in industries like construction or shipbuilding. Hoists lift materials vertically, often used in manufacturing for assembling heavy machinery. Lift Tables adjust the height of loads, enabling ergonomic positioning for workers during packaging or assembly tasks.

Read more about Lifting and Positioning Equipment

-

Unit Load Formation Equipment

Unit load formation equipment organizes materials into manageable units for transport or storage. Pallet Trucks, also known as pallet jacks, move palletized loads short distances in warehouses. Stretch Wrappers secure loads to pallets with plastic film, ensuring stability during transport. Carton Sealers automate the sealing of boxes, speeding up packaging processes in distribution centers.

Read more about Unit Load Formation Equipment

-

Automated Systems

Automation is transforming material handling with advanced technology. Robotic Arms perform tasks like picking, packing, and palletizing, offering precision in high-volume environments like pharmaceutical manufacturing. Warehouse Management Systems (WMS) integrate with MHE to track inventory in real-time, reducing errors and improving efficiency. Sortation Systems automatically sort products for shipping, commonly used in e-commerce fulfillment centers.

Read more about Automated Systems

-

Bulk Handling Equipment

Bulk handling equipment manages loose materials like grains, powders, or liquids. Hoppers store and dispense bulk materials, often used in food processing or chemical industries. Silos provide large-scale storage for materials like cement or grain. Bucket Elevators transport bulk materials vertically, ensuring efficient movement in agricultural or mining operations.

Read more about Bulk Handling Equipment

Choosing the Right Equipment

Selecting the appropriate material handling equipment depends on factors like the type of materials, operational scale, and budget. For instance, a small warehouse might rely on manual pallet trucks, while a large distribution center may invest in AGVs and sortation systems. By understanding the types of MHE available, businesses can optimize workflows, enhance safety, and boost productivity, ensuring they stay competitive in today’s fast-paced industrial landscape.

How to Find Material Handling Equipment Manufacturers Using IQS Directory

Material handling equipment (MHE) is crucial for industries like warehousing, manufacturing, and logistics, enabling the efficient movement, storage, and management of goods. Sourcing the right MHE manufacturer ensures you get high-quality, reliable equipment tailored to your operational needs. IQS Directory is a powerful online platform that simplifies this process by connecting businesses with trusted manufacturers.

Here is a step-by-step guide to finding material handling equipment manufacturers using IQS Directory.

Why Choose IQS Directory for Material Handling Equipment Manufacturers?

IQS Directory is a leading industrial sourcing platform with an extensive database of manufacturers across various sectors, including material handling. It offers several advantages:

- Wide Range of Suppliers: Access manufacturers of diverse MHE, such as conveyors, forklifts, and automated systems.

- Detailed Profiles: Each manufacturer’s profile includes product offerings, certifications, and contact details.

- Advanced Search Tools: Filters help you find manufacturers based on location, equipment type, and certifications.

- Request for Quote (RFQ) Feature: Easily request quotes from multiple manufacturers, streamlining the procurement process.

Step 1: Access IQS Directory and Locate the Material Handling Category

Use the search bar on the homepage by typing “material handling equipment manufacturers” or click the link. Alternatively, browse the categories under “Industrial Equipment” or “Material Handling” to find relevant listings. This will display a list of manufacturers specializing in equipment like conveyors, pallet trucks, and AGVs.

Step 2: Apply Filters to Refine Your Search

IQS Directory’s filters allow you to narrow down your search for the most relevant manufacturers:

- Location: Filter by country or state (e.g., “United States” or “Texas”) to find manufacturers closer to your facility for faster delivery and support.

- Equipment Type: Specify the type of MHE you need, such as “forklifts,” “conveyors,” or “robotic arms,” to focus on relevant suppliers.

- Certifications: Look for manufacturers with certifications like ISO 9001, ensuring quality and reliability.

- Company Type: Select “Manufacturer” to exclude distributors and connect directly with producers.

For example, if you need an ISO-certified conveyor manufacturer in the US, apply these filters to get a targeted list.

Step 3: Explore Manufacturer Profiles

Click on a manufacturer’s name to view their profile, which includes:

- Product Range: Confirm they produce the equipment you need, such as Hytrol for conveyors or Crown Equipment for forklifts.

- Certifications: Check for compliance with industry standards like ISO or OSHA regulations.

- Experience: Look for established manufacturers with years of expertise in material handling solutions.

- Capabilities: Some profiles highlight customization options, which are useful if you need tailored equipment.

Shortlist 3-5 manufacturers that align with your requirements based on their profiles.

Step 4: Request Quotes and Communicate with Manufacturers

Use IQS Directory’s tools to connect with manufacturers:

- Submit an RFQ: Click “Request for Quote” on the manufacturer’s profile and provide details like equipment type (e.g., “belt conveyor with 500 lb capacity”), quantity, and delivery timeline.

- Direct Contact: Use the provided phone number or email to ask about specifications, customization, or lead times.

- Compare Quotes: Review responses to compare pricing, delivery schedules, and additional services like installation or maintenance support.

This step helps you gather the information needed to make an informed decision.

Step 5: Evaluate and Choose the Best Manufacturer

Assess the shortlisted manufacturers based on key factors:

- Quality and Reliability: Ensure the equipment meets industry standards and is durable for long-term use.

- Customization: If you need specialized solutions, like an AGV for a unique warehouse layout, choose a manufacturer offering customization.

- Support Services: Prioritize manufacturers providing after-sales support, such as training or maintenance, to minimize downtime.

- Cost Efficiency: Balance cost with value—opt for a manufacturer offering high-quality equipment at a reasonable price.

Select the manufacturer that best fits your operational needs and budget.

Tips for Success on IQS Directory

- Provide Detailed RFQs: Include specific requirements (e.g., “forklift with 5,000 lb capacity for cold storage”) to receive accurate quotes.

- Prioritize Experience: Choose manufacturers with a proven track record in material handling, ensuring reliability.

- Ask About Technology: Inquire if the equipment includes modern features like automation or IoT integration for better efficiency.

- Confirm Lead Times: Ensure the manufacturer can deliver within your project timeline to avoid delays.