Automated Systems for Material Handling: Revolutionizing Efficiency and Precision

Automated systems are transforming material handling by leveraging advanced technology to move, store, sort, and manage materials with minimal human intervention. These systems, widely adopted in industries such as warehousing, manufacturing, logistics, and e-commerce, enhance operational efficiency, reduce labor costs, and improve accuracy. As businesses strive to meet growing demands for speed and precision, automated systems have become a cornerstone of modern material handling. This article explores the types, applications, and benefits of automated systems in material handling.

What Are Automated Systems in Material Handling?

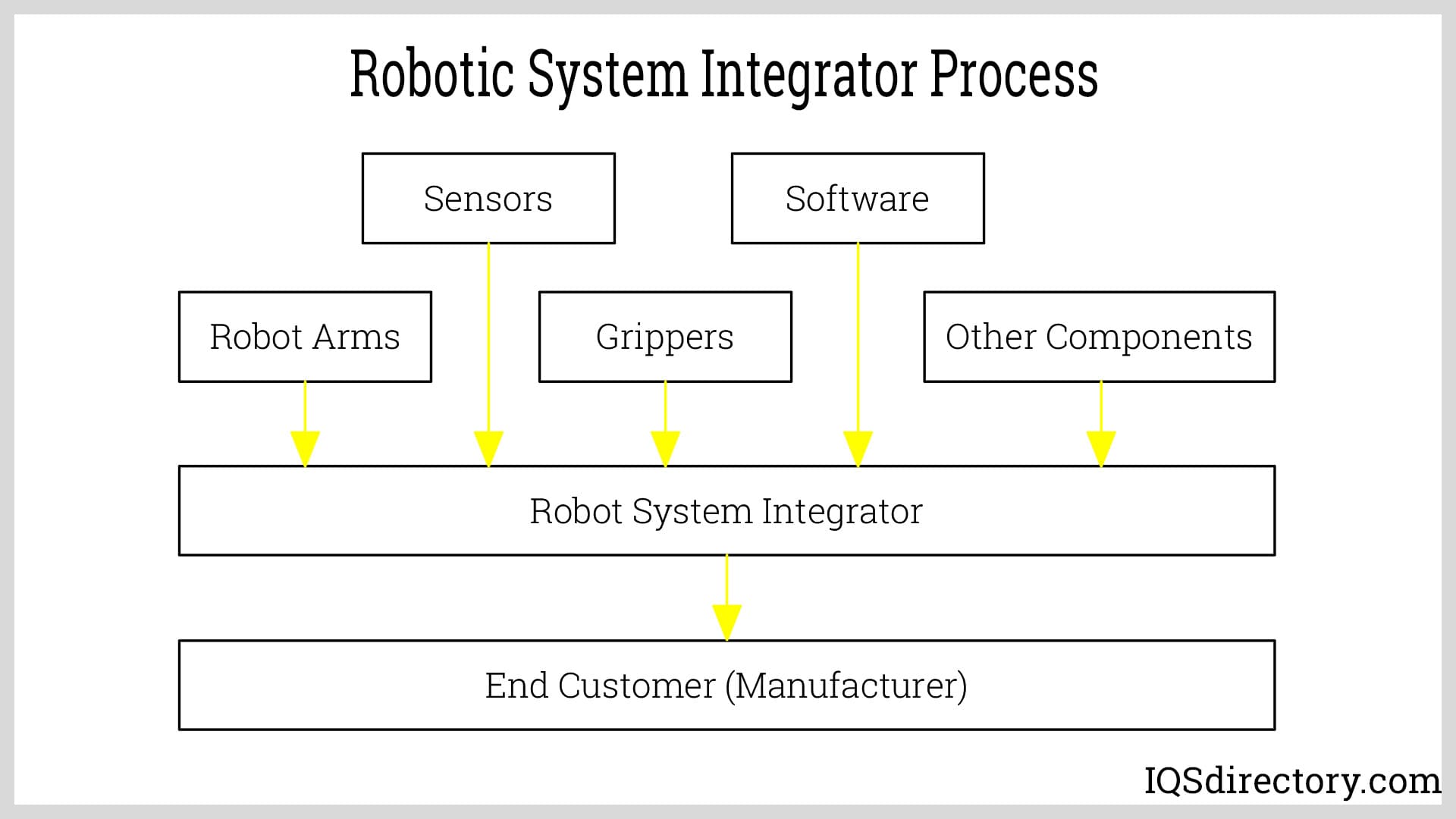

Automated systems in material handling refer to technologies and equipment that use robotics, sensors, software, and artificial intelligence (AI) to perform tasks traditionally done manually. These systems handle the movement, storage, and sorting of materials, often integrating with warehouse management systems (WMS) to optimize workflows. By automating repetitive and labor-intensive tasks, they enable businesses to operate faster, safer, and more efficiently in high-volume environments.

Types of Automated Systems

Automated systems encompass a range of technologies, each designed for specific material handling tasks:

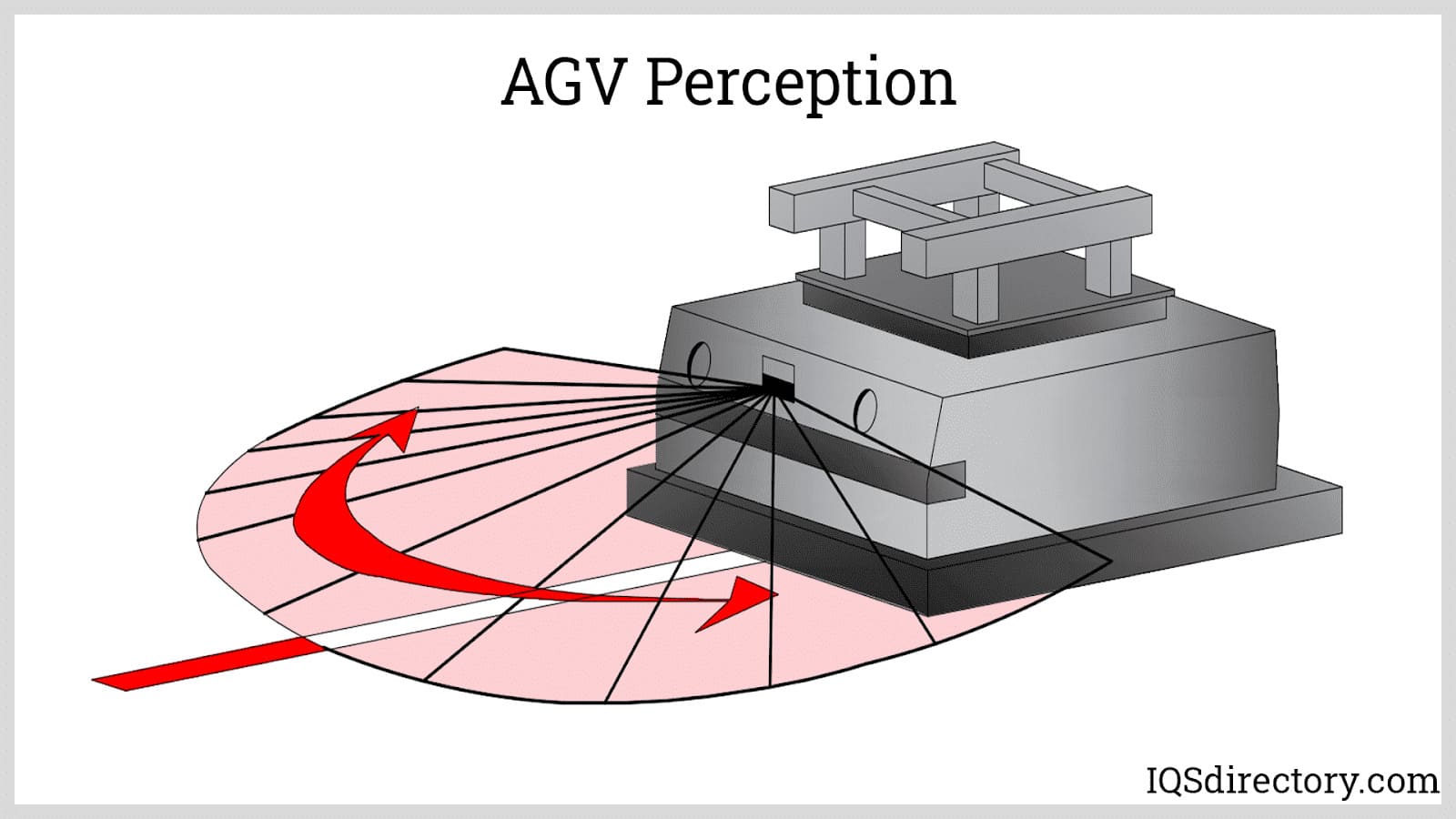

- Automated Guided Vehicles (AGVs): AGVs are autonomous vehicles that transport materials along pre-programmed routes using sensors, magnetic strips, or laser guidance. They are ideal for moving goods in large warehouses or manufacturing plants. For example, an AGV can deliver pallets of raw materials to a production line, reducing manual transport time.

- Robotic Arms: Robotic arms perform tasks like picking, packing, and palletizing with precision. Equipped with vision systems and AI, they can handle diverse items, from small components to large boxes. In e-commerce fulfillment centers, robotic arms can pick and pack 500 orders per hour, far surpassing manual capabilities.

- Automated Storage and Retrieval Systems (AS/RS): AS/RS systems use robotics to store and retrieve items from high-density storage racks. They are often used in pharmaceutical or food distribution, where precision and speed are critical. A mini-load AS/RS, for instance, can retrieve small bins at a rate of 400 per hour, optimizing inventory management.

- Sortation Systems: Sortation systems automatically sort items for shipping based on criteria like destination or order type. Conveyor-based sortation systems with barcode scanners can process thousands of packages per hour, making them essential in logistics hubs for companies like Amazon or FedEx.

- Warehouse Management Systems (WMS): WMS software integrates with automated equipment to manage inventory, track material movements, and optimize workflows. It provides real-time data on stock levels, ensuring efficient order fulfillment. For example, a WMS can direct an AGV to retrieve a specific item from an AS/RS rack.

- Conveyor Systems with Automation: Automated conveyors use sensors and controls to route materials to different areas of a facility. They are often paired with sortation systems to streamline processes like order picking or packaging in distribution centers.

Applications of Automated Systems

Automated systems are used across industries to enhance material handling efficiency:

- Warehousing: AS/RS and AGVs manage inventory in high-volume warehouses, enabling rapid retrieval and delivery of goods for order fulfillment.

- Manufacturing: Robotic arms assemble products or move components between workstations, ensuring a continuous production flow in industries like automotive or electronics.

- Logistics: Sortation systems and automated conveyors sort packages in distribution centers, speeding up shipping processes for logistics providers.

- E-commerce: Robotic arms and WMS handle the high order volumes of online retailers, ensuring fast and accurate order processing during peak seasons.

- Pharmaceuticals: AS/RS systems store and retrieve sensitive items like vaccines with precision, maintaining strict compliance with regulatory standards.

Benefits of Automated Systems

Automated systems offer significant advantages that revolutionize material handling:

- Increased Efficiency: Automation speeds up processes by handling tasks faster than manual methods. For instance, a sortation system can process 10,000 items per hour, drastically reducing order fulfillment times.

- Improved Accuracy: Systems like robotic arms and AS/RS reduce human errors, such as picking the wrong item. Vision-equipped robots can achieve 99.9% accuracy in picking tasks, ensuring order precision.

- Cost Savings: While the initial investment is high, automated systems reduce long-term labor costs and minimize errors that lead to returns or rework, offering a strong return on investment.

- Enhanced Safety: By automating heavy lifting and repetitive tasks, these systems lower the risk of workplace injuries like strains or falls. AGVs, for example, include safety sensors to avoid collisions.

- Scalability: Automated systems can be scaled to handle increased demand, such as adding more AGVs during peak seasons, ensuring flexibility in dynamic environments.

Choosing the Right Automated System

Selecting the appropriate automated system depends on several factors:

- Operational Volume: High-volume operations benefit from AS/RS or sortation systems, while smaller facilities may start with AGVs or automated conveyors.

- Material Type: Robotic arms are ideal for diverse items, while AS/RS systems suit uniform loads like bins or cartons.

- Integration Needs: Ensure the system integrates with existing software, such as a WMS, for seamless operation.

- Budget: Smaller businesses can begin with semi-automated solutions, while larger operations may invest in fully automated systems for maximum efficiency.

<< Go Back

Leading Automation Equipment Manufacturers

Dixon Automatic Tool, Inc. open_in_new

Location: Rockford, IL

A recognized leader in automated assembly products. Stay competitive with Dixon's robotic screwdrivers, auto-fed screw & nut drivers, auto-fed part placers, parts feeding systems & assembly cells, including robotic assembly & vision. Every Dixon product is manufactured to assure accuracy & dependability for repetitive assembly. Dixon supports Machine Integrators with assembly products & stations. Contact us today and we will help you find the best product for your application!

Invio Automation open_in_new

Location: New Baltimore, MI

Invio Automation is a leading comprehensive AGV, AMR, and robotics integrator with 10 engineering and support sites throughout North America. We specialize in heavyweight and assembly line applications.

Advent Design Corporation open_in_new

Location: Bristol, PA

Advent Design’s Manufacturing Automation group has a proven track record in the design and assembly of custom equipment for manufacturing. Company experience ranges from single workstation semi-automated equipment to fully integrated production lines. Additionally, we offer machine safety integration services to assist you in making your machine compliant with current safeguarding standards. Our diverse team members work together with your company to achieve the best solution for your particular needs.

Isotech, Inc. open_in_new

Location: Hatfield, PA

Since 1982, Isotech has been a leader in the automation equipment industry. You can trust the accuracy of our solutions. Our experts at Isotech are always available to assist you with your needs. Feel free to contact us today to learn more information!

Del-Tron Precision, Inc. open_in_new

Location: Bethel, CT

Del-Tron Precision is your one-stop shop for ball & crossed roller slides, multi-axis positioning and motor-ready lead screw stages, air actuators, recirculating slide guides and crossed roller rail sets. Custom linear slides are available. Visit our website to find life/load calculators. Our greatest strength is to offer components which provide a reliable mechanical interface for equipment.